Harness the Strategic Side of Concrete Scanning for Unparalleled Task Success and Top Quality Assurance

In the realm of modern building and construction and framework development, the usage of concrete scanning modern technology has arised as an essential tool for ensuring project success and preserving quality requirements. The real power of concrete scanning lies not only in its capacity to improve project outcomes yet also in its capacity to transform traditional methods, setting a brand-new benchmark for precision and performance in the building and construction industry.

The Relevance of Concrete Scanning

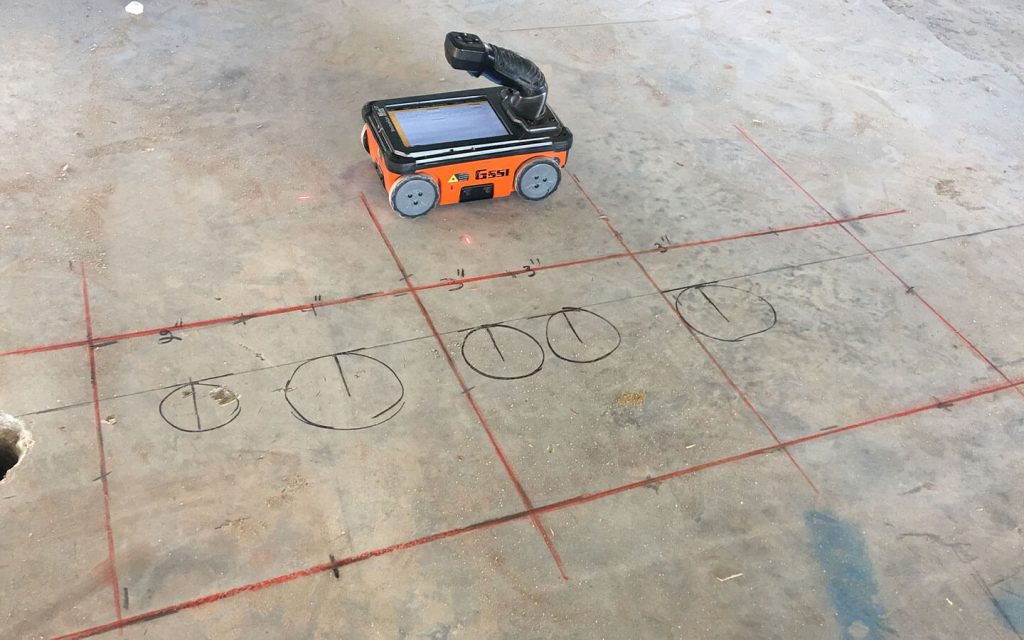

Concrete scanning is an essential step in building and construction projects to guarantee the safety and security and honesty of structures. By using numerous scanning technologies such as Ground Permeating Radar (GPR) and electro-magnetic induction, construction groups can non-destructively review the subsurface of concrete structures to identify potential risks like rebar, avenues, or post-tension cables. This info is vital for project engineers, managers, and specialists to make informed decisions and prevent expensive errors during the building and construction procedure.

Among the key reasons concrete scanning is so crucial is its ability to stop mishaps and injuries on the building site. Unintentionally puncturing an online electric channel or damaging post-tension cables can have catastrophic repercussions, not only in regards to security but additionally in terms of project hold-ups and economic effects. By carrying out complete concrete scanning prior to any exploration, reducing, or coring activities, construction groups can mitigate dangers and create a more secure working setting for everybody entailed.

In enhancement to safety and security considerations, concrete scanning likewise plays a vital duty in making certain the long-term durability and quality of the structure. By spotting any kind of defects or abnormalities hidden under the surface area, such as voids or delamination, very early intervention can be carried out to address these problems prior to they escalate right into even more significant issues. Ultimately, purchasing concrete scanning is a proactive action that can conserve time, money, and resources in the long run, while additionally supporting the highest possible requirements of building and construction excellence.

Advanced Modern Technology for Precise Outcomes

Additionally, 3D scanning technologies provide a detailed sight of the subsurface environment by producing in-depth digital designs. These designs supply useful insights right into the architectural stability of concrete aspects and assist in determining potential weaknesses prior to they intensify into major issues. By including these innovative modern technologies right into concrete scanning practices, building groups can simplify workflows, lower job delays, and guarantee the overall high quality and success of the project. The accuracy and effectiveness provided by these tools add substantially to the job's success by facilitating educated enhancing and decision-making top quality guarantee procedures.

Enhancing Job Performance and Timelines

In addition, concrete scanning allows groups to recognize structural weak points and potential hazards Your Domain Name at an early stage, permitting punctual removal and avoiding crashes that might thwart task timelines. The real-time information provided by scanning tools helps with notified decision-making, resulting in smoother control amongst various professions and stakeholders. This boosted cooperation decreases conflicts, boosts productivity, and eventually speeds up task distribution.

Furthermore, by proactively dealing with issues with concrete scanning, building teams can stick to timetables better, lower downtime, and optimize resource allotment. The ability to find surprise barriers and verify structural stability effectively contributes to overall task performance and timelines, ensuring effective end results and client fulfillment.

Ensuring Security and Threat Reduction

Threat reduction strategies can be boosted through the in-depth information supplied by concrete scanning, making it possible for project groups to make informed choices that lower the possibility of unanticipated events. Additionally, by precisely drawing up subsurface conditions, contractors can prevent pricey rework, delays, and damages to existing frameworks, better adding to overall project security and success. Executing concrete scanning as a routine technique not only guarantees a more secure workplace however additionally infuses confidence in stakeholders concerning the task's dedication to quality and danger monitoring.

Quality Control Through Concrete Scanning

Concrete scanning plays a crucial duty in upholding quality control standards within construction jobs. By using sophisticated scanning modern technologies such as Ground Passing Through Radar (GPR) and Concrete X-ray, task supervisors and designers can ensure the integrity and quality of concrete structures. Through concrete scanning, potential flaws, such as gaps, splits, or enhancing bar congestion, can be discovered non-destructively, permitting prompt interventions to maintain the structural honesty of the task.

Quality control via concrete scanning not just aids in determining existing problems however also allows aggressive actions to avoid future issues that might endanger the security and longevity of the framework. By performing comprehensive scans at key phases of building, teams can validate the accuracy of structural plans, confirm the placement of crucial components, and resolve any kind of discrepancies go without delay. This positive strategy lessens rework, decreases pricey hold-ups, and ultimately leads to the shipment of high-grade, sturdy frameworks that exceed or meet market criteria.

Conclusion

In final thought, concrete scanning plays a critical role in ensuring project success, top quality, efficiency, and safety and security guarantee. The tactical side offered by concrete scanning permits for positive risk reduction and improves overall project management.

In the realm of modern construction and framework advancement, the utilization of concrete scanning technology has actually emerged as a crucial device for guaranteeing project success and keeping high quality standards. By including these sophisticated technologies right into concrete scanning practices, construction teams can improve workflows, decrease project hold-ups, and ensure the general quality and success of the job.Provided the critical nature of project efficiency and timelines in building and construction monitoring, the emphasis now moves in the direction of guaranteeing safety and mitigating threats within the job setting.Concrete scanning plays an essential role in upholding top quality guarantee standards within building and construction projects. By making use of sophisticated scanning technologies such as Ground Penetrating Radar (GPR) and Concrete X-ray, project supervisors and designers can ensure the integrity and top quality of concrete frameworks.